홈페이지를 방문해주셔서 감사합니다.

평일 00시 - 00시

토,일,공휴일 휴무

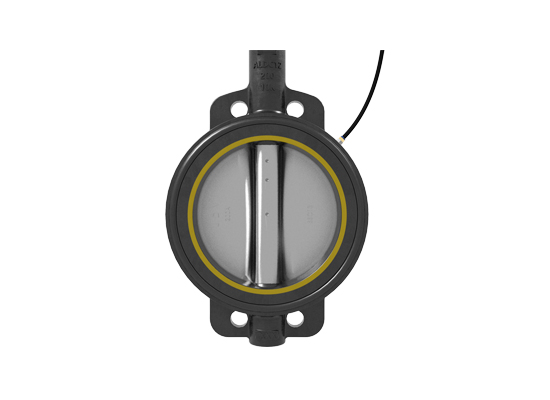

PRODUCTS / Special Butterfly valves

Jeongdo Machinery’s Inflatable Seated Butterfly Valve is an optimal solution designed for piping systems transporting dry air or powder, and for processes requiring frequent actuation.

It offers excellent sealing performance and reliable operation under demanding conditions.

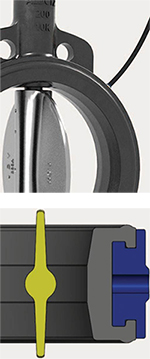

This valve uses compressed air from a pneumatic actuator to inflate the seat, enabling a precise sealing mechanism through the expansion and contraction of the seat. It is designed to maintain a uniform pressure distribution inside the valve, ensuring outstanding sealing performance.

| OPEN | CLOSE (UNSEALED) | CLOSE (SEALED) |

|---|---|---|

|

|

|

- Less Friction

- Minimal seat wear

After the disc rotates, the air is supplied to inflate the seat. The operation method enable no friction occurs between the seat and the disc, damage and wear of the seat are minimized, and the vavle has the longer life cycle.

- Even pressure distribution

As a product using air pressure, it distributes the pressure equally inside the seat and has excellent sealing performance.

The disc with a streamlined shape minimizes the accumulation of powders and sludges in the pipe line.

- Ultra-low torque requirements

Since the torque generated when rotating the disc is low, a smaller actuator can be applied, which enables cost reduction

| Design Standards | |

|---|---|

| Valve Design | API 609 Category A |

| ASME B16.34 | |

| MSS-SP 67 | |

| Flange Drilling | KS 10K, ASME B16.5, EN 1092 |

| Face to Face | API 609 |

| Specfication | |

|---|---|

| Body Type | Wafer |

| Size | 1 1/4 " ~ 24" |

| Flange Connection | KS 10K, ASME 150 |

| PN 10 | |

| Temperature Range | EPDM (-20℃~120℃) |

| NBR (-10℃~80℃) | |

| Silicone (-10℃~150℃) | |

| Max. Allowable Pressure | Full Vaccum to 7 bar |

| Air Supply | Max. 8 Bar to Seat |

| Operator | Pneumatic actuator |

| Material Option | |

|---|---|

| Body | Aluminum Alloy |

| A351-CF8 / CF8M / CF3M | |

| DISC | A351-CF8 / CF8M / CF3M |

| Monel, Duplex | |

| Stem | SS420 |

| SS316 / SS630 (17-4PH) | |

| Seat | EPDM |

| NBR | |

| Silicone |