홈페이지를 방문해주셔서 감사합니다.

평일 00시 - 00시

토,일,공휴일 휴무

PRODUCTS / Eccentric Butterfly valves / Double Offset Butterfly valves

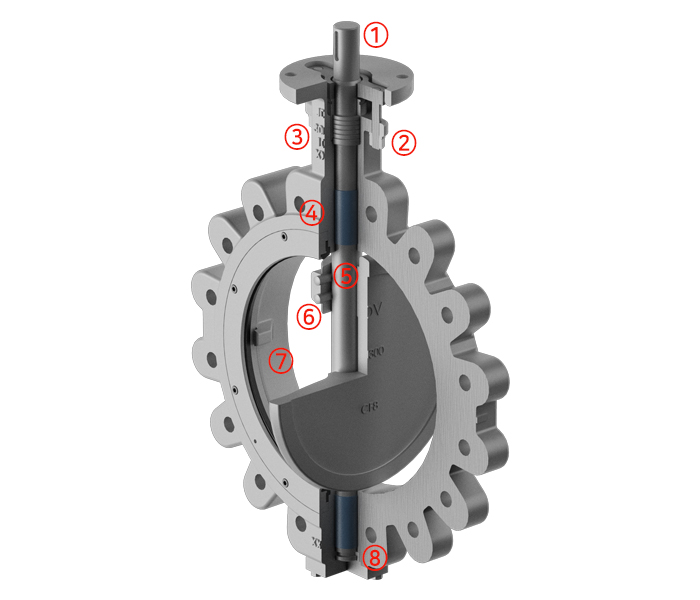

The Double Offset Butterfly Valve from Jeongdo Machinery—also known as a High-Performance Butterfly Valve—features a double-offset design, where the stem is offset from the disc center (1st offset) and the valve body centerline (2nd offset).

This structure enables reliable operation in high-temperature and high-pressure applications. Depending on fluid temperature, the valve is available with either RTFE seat or metal seat options. It is also manufactured in Wafer, Lugged, and Flanged types to suit various piping systems.

Through Jeongdo Machinery's patented technology, the restoring force of the seat is enhanced, improving sealing performance in the reverse direction. An integral stopper is applied to prevent excessive disc movement, thereby minimizing seat damage and extending product lifespan.

RTFE seat stands for Reinforced PTFE, which is a composite material made of PTFE (Polytetrafluoroethylene) mixed with glass fiber and molybdenum.

The valve design complies with API 609 standards, ensuring reliable performance and international compatibility in high-performance butterfly valve applications.

The valve body is tapped to allow Dead-End Service, enabling stable operation at the end of a pipeline without requiring downstream support.

Easy Maintenance

Allows valve replacement or inspection without full system shutdown, as pressure can be maintained on the opposite side even if one flange is removed.

Dead-End Service

Can be securely installed at the end of a pipeline without additional downstream support, making future line extensions and modifications easier.

Installation Flexibility

Easily integrates with flanged piping systems, and is compatible with various pressure classes and industrial environments, providing wide application versatility.

Reduced Leakage Risk

The precise bolting structure ensures accurate alignment between the valve and the pipeline, significantly reducing the risk of leakage at the connection point for stable system operation.

| Design Standards | |

|---|---|

| Valve Design | API 609 Category B |

| ASME B16.34 | |

| MSS-SP 68 | |

| Flange Drilling | ASME B16.5, ASME B16.47 |

| Face to Face | API 609 |

| ISO 5752 |

| Specfication | |

|---|---|

| Body Type | Wafer / Lugged / Flanged |

| Size | 1 1/4 " ~ 64" |

| Flange Connection | ASME 150 / 300 |

| PN 10/16/25/40 | |

| Temperature Range | RTFE (-29℃~200℃) |

| Stainless Steel (-29℃~350℃) |

| Material Option | |

|---|---|

| Body | Ductile Iron |

| A216-WCB | |

| A351-CF8 / CF8M / CF3M | |

| DISC | A351-CF8 / CF8M |

| Monel, Duplex | |

| Stem | SS420 |

| SS630 (17-4PH) | |

| Seat | RTFE |

| Stainless steel |