홈페이지를 방문해주셔서 감사합니다.

평일 00시 - 00시

토,일,공휴일 휴무

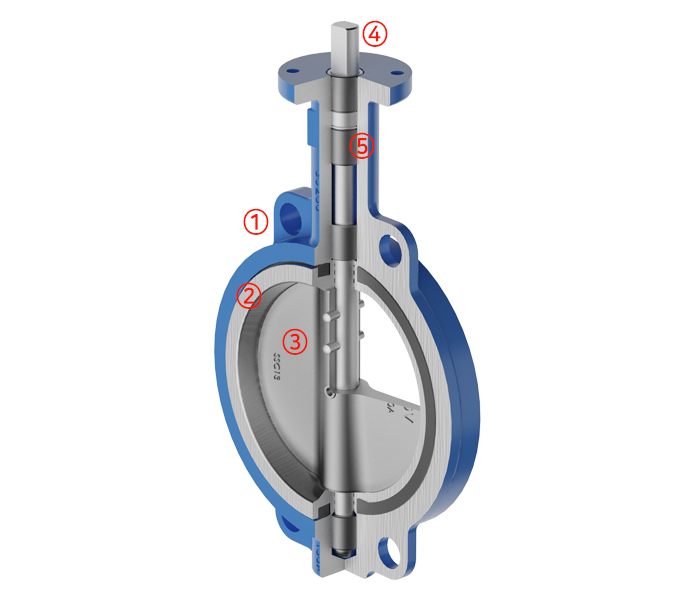

PRODUCTS / Concentric Butterfly valves / Rubber Seated Butterfly valves

Jeongdo Machinery's Concentric Rubber Seated Butterfly Valves are available in Wafer, Lugged, Grooved, and Flanged types, depending on the connection method.

They are designed to suit a wide range of operating conditions and are applicable for various fluids such as water, ultrapure water, oil-free systems, seawater, and chemicals, as well as different pressure requirements.

Made from aluminum alloy, featuring Hard Back Ring (with a shock-absorbing) structure, which significantly improves durability and service life. Its excellent corrosion resistance and light-weight design reduce stress on the pipeline and enhance work efficiency.

4 or more Guide Holes are provided for easy and accurate installation.

(The ALDC12 + shock-absorbing seat (Water Type) model was officially recognized as a Korea Excellent Procurement Product (2022).)

Excellent Corrosion Resistance

Forms a dense and stable oxide film that effectively protects against corrosion.

Light-weight

Approximately 70% lighter than steel or copper, reducing pipeline stress and improving work efficiency.

High Strength

With a tensile strength of 220–240 MPa, it offers excellent strength-to-weight ratio, making it suitable for automotive, railway, and aerospace structural applications.

Eco-Friendly Material and Process

Does not emit harmful substances during chemical reactions. The die-casting process minimizes the release of pollutants such as formaldehyde during production.

| Design Standards | |

|---|---|

| Valve Design | API 609 Category A |

| ASME B16.34 | |

| MSS-SP 67 | |

| Flange Drilling | ASME B16.5 |

| Face to Face | API 609, ISO 5752 |

| Specfication | |

|---|---|

| Body Type | Wafer |

| Size | 2 " ~ 12" |

| Flange Connection | ASME 150 |

| PN 10 | |

| Temperature Range | EPDM (-20℃~120℃ ) |

| NBR (-10℃~80℃ ) |

| Material Option | |

|---|---|

| Body | Aluminum Alloy |

| DISC | A351-CF8 / CF8M / CF3M |

| Monel, Duplex | |

| Stem | SS420, SS431 |

| SS316 / SS630 | |

| Seat | EPDM |

| NBR |