홈페이지를 방문해주셔서 감사합니다.

평일 00시 - 00시

토,일,공휴일 휴무

PRODUCTS / Concentric Butterfly valves / Rubber Seated Butterfly valves

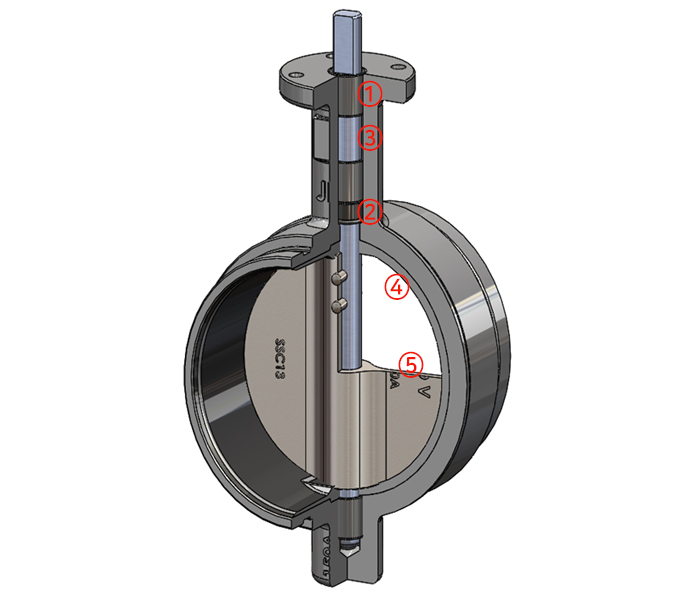

Jeongdo Machinery's Concentric Rubber Seated Butterfly Valves are available in Wafer, Lugged, Grooved, and Flanged types, depending on the connection method.

They are designed to suit a wide range of operating conditions and are applicable for various fluids such as water, ultrapure water, oil-free systems, seawater, and chemicals, as well as different pressure requirements.

Grooved Butterfly Valve is designed for weld-free piping systems and is suitable for seismic-resistant (anti-vibration) piping applications.

Through patents and utility models, the valve achieves bi-directional sealing, and its durability has been verified with certified reliability of materials and components.

Ease of Installation

: No need for additional bolting—over 50% faster installation compared to flange-type valves.

Stability

: Excellent resistance to seismic activity and vibration, with built-in flexibility for expansion and contraction of piping systems; suitable for seismic piping designs.

Ease of Maintenance

: Quick and simple coupling connection allows for easy maintenance and replacement.

| Design Standards | |

|---|---|

| Body Type | Grooved |

| Valve Design | MSS SP-67 |

| Grooved end | AWWA C606 |

| Face to Face | MSS SP-67 |

| Specfication | |

|---|---|

| Body Type | Grooved |

| Size | 1 1/4 " ~ 24" |

| Flange Connection | ASME 150 |

| PN 10/16 | |

| Temperature Range | EPDM (-20℃~120℃ ) |

| NBR (-10℃~80℃ ) |

| Material Option | |

|---|---|

| Body | Ductile Iron |

| DISC | A351-CF8 / CF8M |

| Stem | SS431 |

| Seat | EPDM |

| NBR |